|

and how not

to cook your turtle.

by Bob McNally

How To Find, Choose & Treat Driftwood

Let’s start

with what constitutes driftwood

For most folks, driftwood is any piece of wood that has

lost its bark. But how that wood lost its bark is what makes the difference

between which wood will work out in the long run. Wood that is collected from

the forest floor usually doesn’t work out well. A piece of wood that lays on the

forest floor for any length of time has lost it’s bark because a multitude of

insects and fungus wormed their way into the cambium layer just under the bark.

The cambium layer is the newest wood in the tree and is also the softest. Once

the cambium layer is devoured the bark is now detached from the wood. But,

because the wood is lying undisturbed on the forest floor, the bark remains in

place, creating the perfect cover for the next wave of wood devouring insects

and fungi. The fungi actually do more harm than the insects because they

permeate the wood, rendering it soft and utterly useless.

Wood that manages to fall into the water loses its bark a

little differently. The cambium layer breaks up rather quickly. In most

hardwoods it’s only about 1/8” thick or less. But in water, once the bark is

loose, the water washes it away. The dark hiding places that fungi need to do

their damage is gone. The only thing left to break down the wood is the erosive

effect of the water, which gives the wood its soft edges and polished

appearance. Exactly what we’re looking for in a piece of driftwood.

In the hunt for driftwood, I recommend using only water

borne driftwood. The rivers are the best source. They’re usually hundreds of

miles long and they’re usually lined with trees. The best places to start your

search are any cove. Dams, bridge abutments, and sharp turns in the river. You

can find driftwood on ocean beaches but it’s not as plentiful.

What to do to

your driftwood to make it safe

I’ve read suggestions ranging from boiling the wood, to

baking it in an oven, to giving it a salt bath, to bleach solutions, etc....

None of which are easy to pull off if you have a three foot piece of wood.

The first thing to do is thoroughly dry the wood.

Store the wood for at least two months in a dry, airy place (not

your attic; if there're any woodborer larvae or the like residing in the wood,

this is a good way to introduce the little vermin into your house!). Placing it

in direct sunshine once in a while will speed up the drying process. Some place

with low humidity will help. Well-dried wood is crucial for step two to work. I

also chisel away any bark and all soft spots. These soft spots are the result of

fungal breakdown, as in decomposition. We only want very dry, good solid wood to

work with.

Once I’m

satisfied the wood is dry, step two is to fumigate. I use the household flea

foggers sold in house wares store. I pile all of my dried wood into the tool

shed, which for me is usually a pick-up truck load. Block up all of the

openings with newspaper and use one can of fogger. The instructions on the

can will tell you that you can return to the room after two hours. I’m not

that trusting. I don’t go back into the shed for a couple of days. Even

though the toxins self-neutralizes in two hours, I give it a few weeks just

to be safe. After the three to four months, between drying, fumigation and

neutralizing, I’ve got driftwood I can almost trust. There’s more to be done

later in the final cleaning process.

Warning:

The following represents our best lay understanding of safety

information pertinent to defoggers with the active ingredient

Tetramethrin for use in

driftwood preparation for turtle enclosures, provided in good faith. We do

not & cannot make professional claims as to the safety or lack thereof of

such products (for human, animal or plant), anyone choosing to use the

products in this manner must assume full responsibility for such use, & we

strongly recommend first researching the matter yourself to ascertain the

degree of safety & risk.

A Word About Roach Foggers

Note: Many will be wary of using commercial

insecticides on an enclosure appliance for fear of harmful residues.

In the foggers I’ve used the

active ingredient is Tetramethrin. It’s been studied thoroughly, & lots

of info. is available on its properties. Its 'claim-to-fame' is its

alleged harmless nature after quick degradation. It degrades in less

than two hours! Consider its aerosol density is 0.05% in a 12x12 room.

In tests on mice, rats, dogs, rabbits, and birds, it’s been found to

render no harm to DNA or chromosomes. In tests ranging from 90 days up

to two years, with direct ingestion rates of 200mg up to 1500 mg a day,

the only significant change was a mild weight loss in tested subjects

over control animals. The same results were confirmed in direct

inhalation tests. In the feeding tests, 95% to 100% percent of the

degraded by-product (oxidized Tetramethrin) was recovered in the feces.

In other words, it passes right through the system. In rabbit eye tests,

96.5% pure doses administered directly in to the eye only created slight

hyperemias. All irritations disappeared within 48 hours. In skin tests

with mammals and birds, once again with 96.5% pure solutions

administered to bare skin there were produced no reactions or allergies

in any of the subjects. Yes, this stuff is toxic to fish in its use

form, but degradation renders it harmless even here.

Bottom line:

Industry tests can't seem to make this stuff harm anything but it's

intended targets. Once introduced into the air it is absolutely

harmless after two hours.

Final Notes: Don't boil the wood to sterilize it; this can harm the

piece (the wood expands when boiled; this can weaken it & open small gaps

letting in more water & hastening decomposition). I also recommend against 'finishing' the wood with any sealant, even

if thought to be aquarium-safe. Let's take an example; Marine Epoxy finish.

Absolutely not. Unless you dip the entire spot, then maybe. There're too many

nooks and crannies in the wood. Every one would have to be

thoroughly filled, otherwise, as soon as any moisture gets beyond

the epoxy seal you'll get fungal growth. It'll be black, very ugly and

trapped. We're not dealing with low moisture content here. The

ever present changes in humidity from the on/off cycle of the

basking light cause a lot more expansion and contraction than

normally experienced. The epoxy will actually cause faster

breakdown of the wood. All of the "clear" coat finishes also have a

fair amount of silica in their make-up and as it breaks down, you'll

be feeding algae their favorite food.

-------------------------------------------------------------------------------

How To Design & Build Your Driftwood

Basking Platform

In the wild there are many variables that impact basking (i.e.: temp.s of the

water & air, time of day, cloud cover, trees & other shading cover, breezes,

constant movement of the sun). We can’t offer this variety in our tanks, only a

largely constant set of theoretically ‘optimal’ conditions with limited variety

(i.e.: the water is heated & the basking lamp on or off). We plunk a chunk of

something in the tank under a light bulb and call it a basking spot. Often the

spots are too small to offer a good range of temp.s for thermo-regulation. It’s

either in the water or on the platform.

What I offer is no perfect solution, but

it gives turtles some place else to go, & even if it’s just 8” away, it

makes a difference. With a well-designed driftwood basking platform you can give

your turtle the choice of varying degrees of warmth without sacrificing swimming

area.

Wild turtles bask on everything

from muddy banks to rocks, but basking species often prefer a tree that has

fallen into the water. The turtles straddle the semi-submerged limbs or rest on

the trunk. Watch long enough & you’ll see them slowly turn themselves against

the sun. They often start out facing the sun to dry off but then turn themselves

to get dry the rear end. A secondary benefit is that most of their plastron is

exposed to the air and also gets dried off. Granted this is just my theory, but

after a few hundred hours of observation, I think I answered my biggest

question. Why do most of the turtles face the same direction basking on a log

and this is my theory.

|

|

|

Photo by

Richard Lunsford |

|

|

|

Photo by

Richard Lunsford |

Look closely & you’ll see four turtles on this limb. Now

suspending a limb across the top of your tank in just that perfect way allowing

both access and a way to get fully dry is tricky. But we’ll do our best to

recreate it.

You’ll need enough driftwood to have a vertical post strong

enough to support a horizontal piece about three times the length of your turtle

and at least half its width. For the base, I prefer slate. Flooring slate works

well. It has sufficient thickness to be drilled and hold a screw without

cracking or flaking away. It can be purchased in 12” x 12” squares for just a

few dollars per piece.

The tools involved can be intimidating. I own several power

tools that make this kind of work a snap; you may need to buy or borrow. This

equipment requires skill & if you aren’t familiar with how these tools operate I

suggest you don’t attempt this project. At a minimum you need a good

full-size

hand-saw, better still is a reciprocating saw

& best of all, the ultimate tool for this work is a

band-saw. NEVER ATTEMPT TO CUT ROUND OBJECTS WITH A

CIRCULAR SAW. A CIRCULAR SAW WILL BE OF NO USE WITH THIS PROJECT. A drill

is a must & a free standing drill press is better. You need: Masonry

Drill Bits: 3/16” for the screw shaft

and 3/8” for the screw head. Wood Bits: 1/8” and a

3/8” or a pocket hole bit. Choose screws designed for outdoor use

(the vinyl-coated type is the best). A sharp chisel and lots of 100

grit sandpaper

(a higher-end option would be a motorized sander

(drill-mounted) of some kind (not a grinder); the best

option would be an oscillating spindle sander or a sand-blasting set-up.

Our Equipment List:

1.)

Hand-Saw if not Reciprocating

Saw if not Band-Saw. No circular

saw!

2.)

Power Drill if not a Drill

Press.

3.)

Masonry Drill Bits: 3/16” (for

screw shaft) & 3/8” (for screw

head).

4.)

Wood Bits: 1/8” & 3/8” (or a

pocket hole bit).

5.)

Outdoor screws (ideally

vinyl-coated.

6.)

Sharp Chisel.

7.)

Lots of 100 grit Sandpaper if

not an Oscillating Spindle

Sander or Sand-blasting setup.

Next measure the enclosure to

decide what you need to build.

1)

Measure the

interior length of the tank.

2)

Measure the

interior width of the tank.

3)

Measure the

water line from the bottom of the tank.

This is the most

crucial measurement.

You must establish a

common waterline

because once built, you

don’t want to tear apart the basking platform to

adjust it higher or lower.

4)

Measure where

the basking light is

in relation to the tank.

I find working from the back and the left side is

easiest. E.g. let’s say the light is 10” from the

left and 9” from the back. This is your heat light’s

hotspot. Decide whether you want the basking

platform centered under the hotspot or be off to one

end or the other (this determines the range of

temp.s your turtle is offered).

Let’s start with the piece of wood you have chosen

to make the basking platform out of. I start with a handful of pieces to choose

from.

|

|

|

Photo by Bob

McNally |

For my example:

The intended turtle is

8” long SCL living in a

150 gallon aquarium. The

basking light is

centered in the tank.

The turtle’s owner also

wants the basking spot

to be centered in the

tank. So, out of the

heavy pieces on the left

I chose this one.

|

|

|

Photo by Bob

McNally |

The next choice to make

is the supporting trunk

and any aesthetic

branches you want to

add. I have discovered

that adding branches

that reach just below

the surface afford the

turtles places to cling

to while sleeping at

night. I call these sleeper branches. I

have an array of wood to

choose from in this

picture.

|

|

|

Photo by Bob

McNally |

Okay, it’s time to get

our hands dirty. First up: take your

chisel and pare away any

and all soft or loose

wood. Scrape away any

bark. When you’re sure

that what’s left is all

solid wood, then sand,

sand, and sand some

more. A minute layer of

the entire old surface

must be removed. In

order to avoid the white

flowing fungus (harmless

but ugly) that manages

to bloom after driftwood

is re-hydrated, you must

either sand or

sandblast. Now

we’re ready for the

first cut. In order to

mount the basking spot

on the vertical post, we

need a flat area to

mount it to. This is

where the band-saw comes

in. I cut the log in

half down its length.

|

|

Photo by Bob

McNally |

This can also be done by

clamping the log

vertically in a vice and

either hand-sawing the

log down its length or

using a reciprocating

saw. The end result is a

reasonably flat-bottomed

basking platform and the

bonus is…… the cut-off

piece becomes the access step for the

turtle. Whatever way the

log curves, you simply

reverse the direction

with the cut-off piece

like so.

|

|

Photo by Bob

McNally |

Use

the 1/8” wood bit to

pre-drill and then

secure the step to the

basking spot. Where

the step and the spot

meet is where you want

the waterline to end up

at. This gives the

turtle a submerged area

to climb out on and a

basking spot that

extends high enough out

of the water that it is

always dry (important

for a healthy plastron).

Next up:

Choose your vertical

support pole. Clean it

up like you did the

basking spot. Now let’s

take that waterline

measurement and simply

deduct the thickness of

the base slate. In the

case we’re working on,

the waterline was 21”. I

cut the vertical post to

20.75”.

|

|

Photo by Bob

McNally |

What you see here is the

drill, the specialized

pocket hole drill

bit, pocket hole guide

(blue thing), clamp,

a piece of wood with a

“V” cut into it, and the

supporting log.

|

|

Photo by Bob

McNally |

This is what it all

looks like when

drilling. The clamp

holds the V and the jig in place on the

round log, while the

two-stage pocket hole

bit drills a pilot

screw-hole at exactly a

15 degree angle. I drill

at least three of these

holes as evenly apart as

my eye can tell around

the top of the trunk.

These angled holes allow

me to screw directly

into the underside of

the basking spot. The

alternative is to drill

down through the top of

the basking spot into

the trunk. That route

requires 3” screws and a

really good eye if you

want to get multiple

screws in place for

rigidity. You can

“eyeball” the angled

holes, but the jig just

makes it so much

simpler.

The next big step

is where and how to

place the vertical post

on the slate base.

|

|

Photo by Bob

McNally |

The

drill bit on the left is

the 3/16” masonry bit

and the bit on the right

is the 3/8”. The yellow

screw is the vinyl

coated exterior screws

that I use. They’re

about $5 a box.

I place the support pole

on the slate somewhere

near the center and

trace around the trunk

with a pencil. Then it’s

over to the drill press.

|

|

Photo by Bob

McNally |

You can see the pencil

outline of the trunk.

I’ve drilled the

‘through holes’ with the

1/8” masonry bit from

the top. I then flip the

slate over and change-up

to the 3/8” bit and

countersink the holes.

This gives the

screw-heads a place to

lock in and keeps the

base from wobbling.

Always back the slate up

with a piece of scrap

wood to prevent the

slate from breaking out

when the drill bit comes

through.

|

|

Photo by Bob

McNally |

This was the end result

of this project. The

additional trunks are

the sleeper branches I

mentioned earlier. They

are attached to the base

in the same manner as

the support trunk.

Because of the height of

this particular basking

spot I purposely snugged

up the one sleeper

against the back of the

basking platform and

screwed the branch to

the platform for extra

support. Before I do my

final screw tightening,

I apply a thin layer of

aquarium silicone to the

bottoms of any vertical

trunks. It helps keep

the water from wicking

up inside the wood.

You

can expect your basking

spot to last at least

three years. I presently

have two that are that

old and I can tell that

they still have an easy

three more years in

them.

Maintenance:

When I do a total

cleanout, say once every

nine months or so, I

take the platforms into

the shop and scrape away

the algae and snug up

the screws.

Good Luck,

Bob

McNally

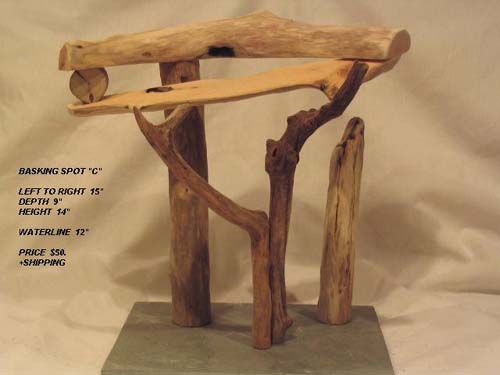

Appendix I.) Some

Completed Examples.

Every piece is a unique

piece of artistic

expression, whether you

design an elaborate

piece with several

sleeper branches or a

utilitarian basic

platform. You can aim

for a 'swampy' look or

otherwise customize your

design for a given

effect.

Platform 1. Tuwhada's

Platform.

|

|

26"

left-to-right,

made for 21"

water-line,

used by 2

RES (8 & 9"

SCL). |

|

Photo by Bob

McNally |

Platform 2. Denise's

Platform.

|

|

Made for

softshells -

lack of

sleeper

branches to

maximize

unobstructed

swimming

space. |

|

Photo by Bob

McNally |

Platform 3. One of

Jan O.'s Platform's.

|

|

This one has

sleeper

branches & a

balanced

look. |

|

Photo by Bob

McNally |

Platform 4. Lovely

Lisa's Platform.

|

|

Rear View.

You can 'get

a little

wilder' with

your style. |

|

Photo by Bob

McNally |

|

|

Front View.

Consider

weight

distribution

when

choosing

your base

slate piece. |

|

Photo by Bob

McNally |

Platform 5. Another

Piece (Owner

Unspecified).

|

|

There's a

lot of

flexibility

in design. |

|

Photo by Bob

McNally |

Platform 6. Another

of Jan O.'s Platforms.

|

|

Note the

balanced,

'little

forest'

look. |

|

Photo by Bob

McNally |

Platform 7. Another

of Jan O.'s Platforms.

|

|

Another of

Jan O.'s

Platforms. |

|

Photo by Bob

McNally |

Platform 8. Another

Piece (Owner

Unspecified).

|

|

Note the

extended

length sleep

branch on

this piece. |

|

Photo by Bob

McNally |

Platform 9. Lynn's

Platform.

|

|

Front View.

Designing

larger

platforms

for deeper

water setups

gives you

more room to

design

striking

pieces. |

|

Photo by Bob

McNally |

|

|

Rear View.

You can use

short,

'bottom'

pieces to

make a more

naturalistic

floor

terrain. |

|

Photo by Bob

McNally |

latform 10. Unusual

Platform Project - Owner

Unspecified.

|

|

This

platform was

designed for

a long, thin

tank with

non-centered

lighting.

The highest

point is

beneath

the

off-center

basking

light. This

is the basic

main basking

platform. |

|

Photo by Bob

McNally |

|

|

You can clearly

see how much

sleeper branches

add to a

platform, both

for the turtles'

comfort & your

tank's aesthetic

look. |

|

Photo by Bob

McNally |

|

|

Planning:

The 'X' is

where the

basking

light shines

down & the

blue

rectangle

the tank

wall

perimeter. With

the basking

platform

against the

back of the

tank you

must be sure

your turtle

can't stand

on it, grab

the tank's

top rim &

escape! |

|

Photo by Bob

McNally |

|